Mining Solution -Mineral Sorting / Ore Sorting / Quartz lumps sorter

Payment:

T/T,L/CProduct Origin:

Hefei,ChinaShipping Port:

Shanghai / NingboLead Time:

Within 7-20 daysProduct Name:

Ore SortingWarranty:

2 yearsMachine Function:

Color sortingCertificate:

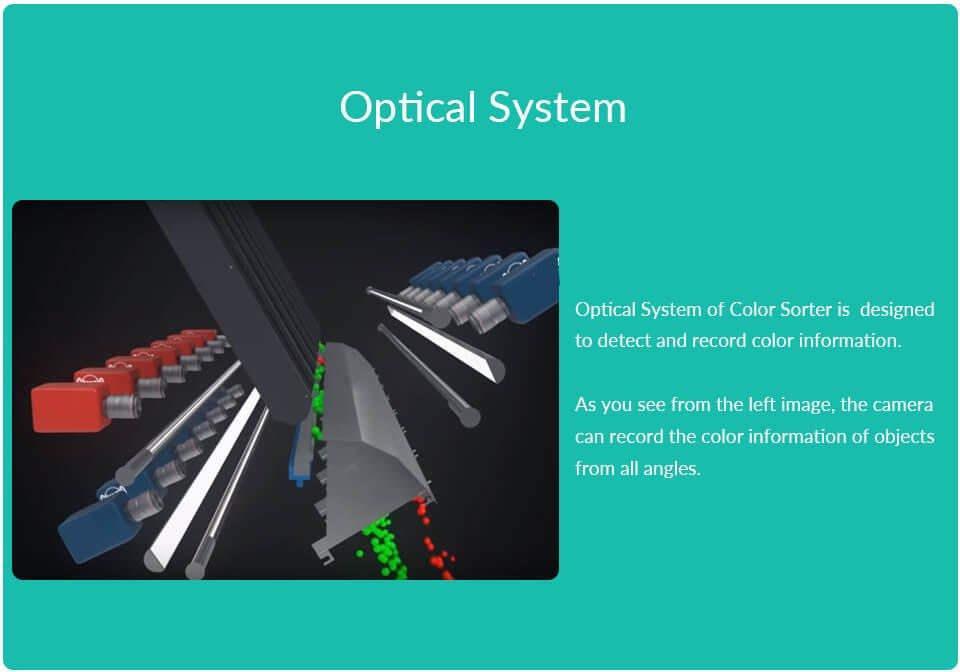

CEOre sorting is used in the early stages of mineral processing and essentially involves separating high-grade from low-grade materials. The technology behind ore sorting has evolved, meaning the process can now operate at higher throughputs and accuracy. Given these advances in technology, the question is: is ore sorting suited to your operation?How dose ore sorting help you ?

|

Model |

BTDKS1200-A |

Power(KW) |

8 |

|

Capacity(T/H) |

40(6cm≦d≦10cm) |

Air Pressure(Mpa) |

0.6(6cm≦d≦10cm) |

|

20(3cm≦d≦6cm) |

0.5(3cm≦d≦6cm) |

||

|

12(1cm≦d≦3cm) |

0.4(1cm≦d≦3cm) |

||

|

8(d≦1cm) |

|||

|

|

|

0.3(d≦1cm) |

|

|

Sorting accuracy(%) |

≧99.9 |

Consumotion(L/min) |

≦5000 |

|

Optimized carryover rate |

≧30:1 |

Weight(kg) |

3500 |

|

Power Supply |

AC220V 50HZ |

Dimension(LxWxH:mm) |

4800*3352*2660 |

Ore sorting is a process of separating valuable minerals from waste rock, based on their physical and chemical properties. Ore sorting can help you in various ways, such as:

1.Improved Efficiency: Ore sorting can significantly improve the efficiency of the mining process. By separating valuable minerals from waste rock early in the mining process, it reduces the amount of material that needs to be processed, thereby reducing the processing time and costs.

2.Increased Yield: Ore sorting can also increase the yield of the mining operation. By removing waste rock early in the process, it ensures that more valuable minerals are recovered, thereby increasing the overall yield of the mining operation.

3.Improved Grade Control: Ore sorting can also improve the grade control of the mining operation. By accurately separating valuable minerals from waste rock, it ensures that the ore fed into the processing plant is of a consistent grade, which can help to improve the quality of the final product.

4.Reduced Environmental Impact: Ore sorting can help to reduce the environmental impact of the mining operation. By removing waste rock early in the process, it reduces the amount of material that needs to be processed, thereby reducing the energy consumption and emissions associated with the processing plant.

5.Enhanced Safety: Ore sorting can also enhance the safety of the mining operation. By removing waste rock early in the process, it reduces the amount of material that needs to be handled and processed, thereby reducing the risk of accidents and injuries.

6.In summary, ore sorting can help you to improve the efficiency, yield, grade control, environmental impact, and safety of your mining operation. By implementing ore sorting technology, you can reduce costs, increase profitability, and make your mining operation more sustainable.