Payment:

T/T,L/CProduct Origin:

Hefei,ChinaShipping Port:

Shanghai / NingboLead Time:

Within 7-20 daysProduct Name:

Ore SortingWarranty:

2 yearsMachine Function:

Color/material sortingCertificate:

CENon-metallic minerals: potassium feldspar, quartzite, talc, phosphate rock, calcite, dolomite, andalusite, fluorite, vermiculite, mica, bentonite, kaolin, barite, feldspar, quartz, calcium carbonate, pebbles, Cryolite, garnet, limestone, manganese ore, etc.

Black ore: monocrystalline silicon, polycrystalline silicon

Non-ferrous ore: copper, antimony, mercury, lead, zinc, tin, nickel, magnesium, cobalt, aluminum, bismuth, silica

Precious metals: gold, silver, zirconium, tungsten, molybdenum, tantalum niobium

HT Process ore color sorter, which can be dry or wet selection, can customize unique ore sorting solutions, which saves time and manpower of enterprises, and promotes both economic and social benefits of enterprises.

Water-based ore sorting machines, also known as hydrocyclones or water-washing ore sorters, offer several advantages in the mineral processing industry. It can sort quartz after washing directly ,no need dry it,so it can save the costs of yours.After sorting ,accepted pure can reach 99.9%.

|

Model |

BTDKS1200-A |

Power(KW) |

8 |

|

Capacity(T/H) |

40(6cm≦d≦10cm) |

Air Pressure(Mpa) |

0.6(6cm≦d≦10cm) |

|

20(3cm≦d≦6cm) |

0.5(3cm≦d≦6cm) |

||

|

12(1cm≦d≦3cm) |

0.4(1cm≦d≦3cm) |

||

|

8(d≦1cm) |

|||

|

|

|

0.3(d≦1cm) |

|

|

Sorting accuracy(%) |

≧99.9 |

Consumotion(L/min) |

≦5000 |

|

Optimized carryover rate |

≧30:1 |

Weight(kg) |

3500 |

|

Power Supply |

AC220V 50HZ |

Dimension(LxWxH:mm) |

4800*3352*2660 |

IS IT A HEADACHE TO SEPARATE ORE IN A HIGH DUST AND HIGH POLLUTION ENVIRONMENT?

In the past, non-metallic mining enterprises used manual separation, which had high labor cost. How to improve the efficiency? Ore color separator came into being! With the application of color separation equipment in the separation of non-metallic minerals, HT Process takes the lead in improving the color separation technology. The latest series of ore color separators, with a complete range of types, can provide different color separation schemes of ore from 120 mesh to 5 cm, which can basically meet the demand of separation in the market.

HT Process series is a dry separation stone color separator, which is specially customized for ore separation in high dust and high pollution environment. Three special guarantees are adopted, including high-definition telephoto lens, material lamp, condenser device, and dust removal device before material and blowing nozzle, which solves the problem of ore separation in high dust environment.

1. Image Acquisition System

Using ultra-high full-color industrial special lens, higher resolution, smaller distortion, and deep recognition of small and fine ordinary color sorters cannot select other impurities.

2. Image Processing System

High-end full-color line scanning technology, cutting-edge DSP+FPGA processing technology, and complex algorithms combining color and shape with multiple modes provide a "color selection + shape selection" solution for different ore particle sizes.

3. Advanced Optical System

The low stray light imaging optical path system can identify the difference in low light, the original wide viewing angle technology, the new LED optical system, according to the change of the ore sorting material environment, automatically adjust the light source to achieve the best sorting function.

4. Special Feeding and Conveying System for Ore

According to the characteristics of large, small, dry and wet ore particles, the crawler and vertical conveying methods are adopted to ensure uniform feeding and conveying; the design of easy-to-replace wear-resistant parts is more suitable for harsh industrial and mining environments.

5. Clean the Dust Removal System

An automatic dust removal system is added to realize all-round dust removal and protection. It can be tailored according to special minerals to ensure the stability of the sorting effect.

6. Customized Sorting Structure

The crawler type and vertical structure are adopted to meet the sorting requirements of different particle sizes, reduce repeated crushing and improve economic benefits.

1. Precise structure design avoids the interference of water mist on sorting and identification, and the output is higher.

2. Wide selection range, suitable for ore particles ranging from 10-120 mm in size.

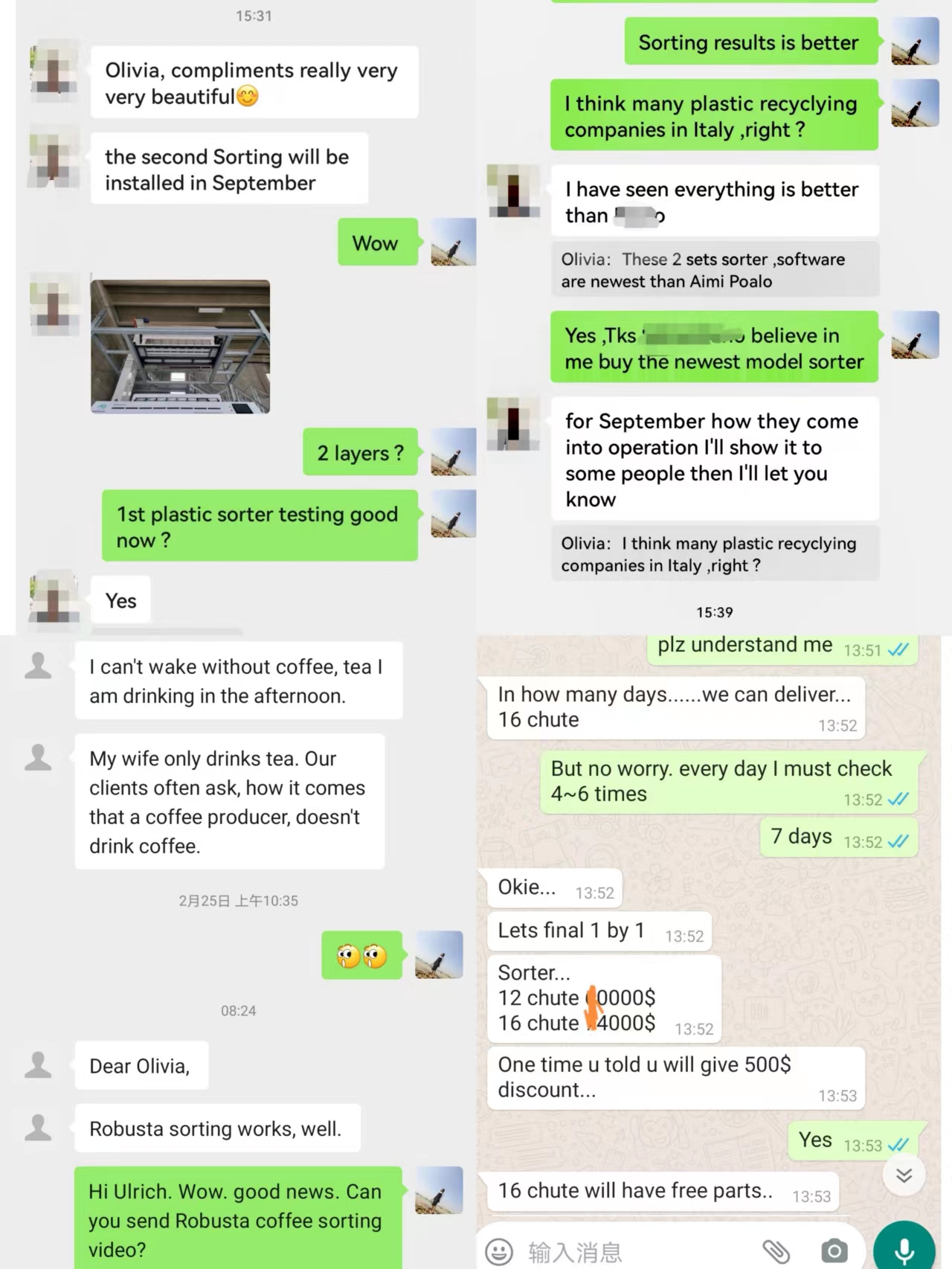

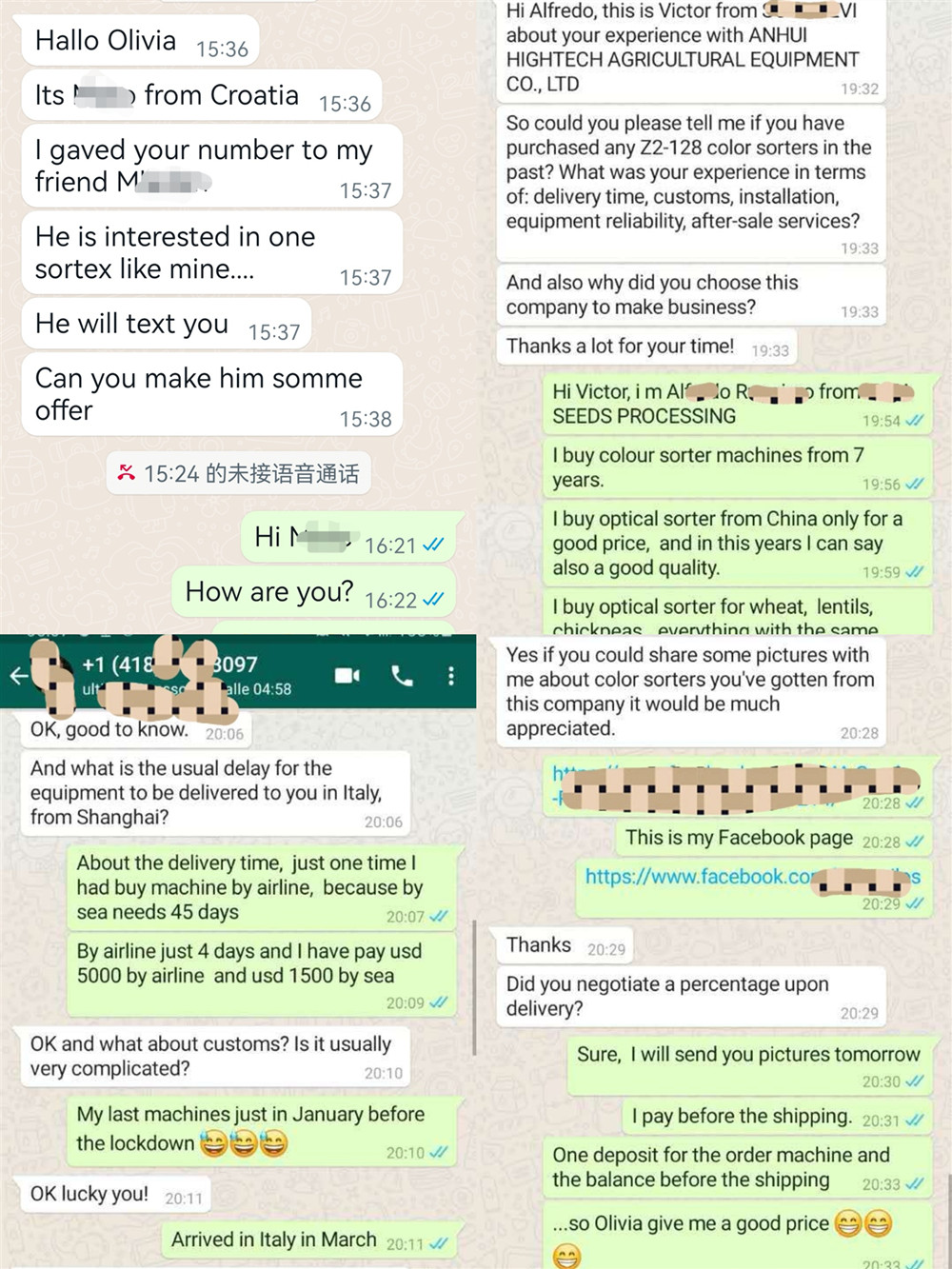

Customer feedback is the driving force behind our progress:

Plywood Case is Suitable for Sea/Road/Air Transport:

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia ,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.

We have many installation cases and working videos.Please contact us freely if you need.