Plastics play a ubiquitous role in our modern world, being integral to various industries ranging from packaging to automotive manufacturing. With the increasing demand for high-quality plastic products, ensuring the purity and consistency of plastic materials has become paramount. In this context, the application of plastic sorting machines has emerged as a crucial technology in the sorting and classification of plastics.

Plastic sorting machine utilize advanced optical sensing and sorting technologies to accurately identify and segregate plastic materials based on their color properties. This technology is particularly effective in distinguishing between different types of plastics and removing contaminants, thereby enhancing the quality and value of the final plastic products.

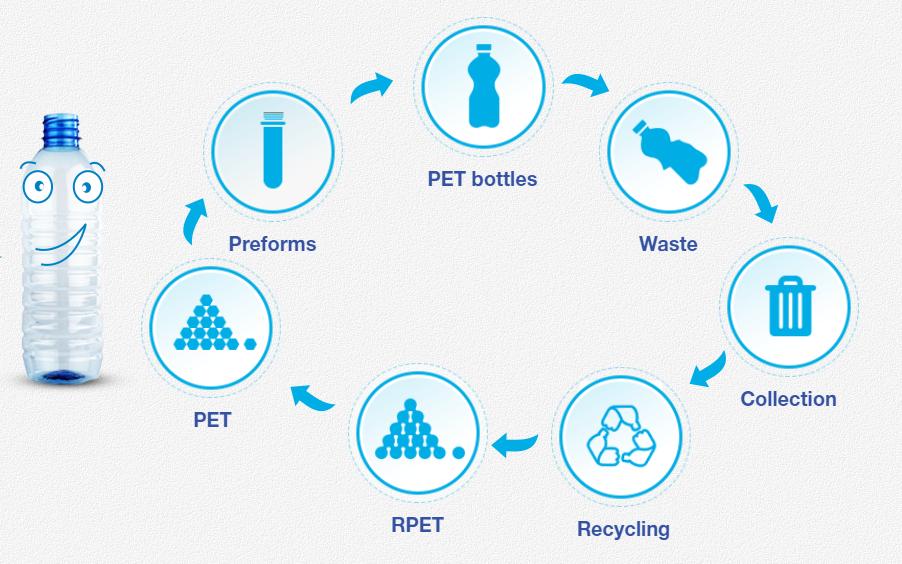

One of the primary applications of plastic color sorter is in recycling facilities. The sorting process in recycling plants involves separating various types of plastics, such as PET (polyethylene terephthalate), HDPE (high-density polyethylene), PVC (polyvinyl chloride), and others, to ensure that they can be recycled efficiently. Plastic color sorters play a vital role in automating this sorting process, enabling rapid and precise identification of different plastic types, regardless of their shape or size.

Furthermore, plastic sorting are instrumental in removing impurities and contaminants from recycled plastic streams. These impurities may include non-plastic materials, such as paper, metal, or glass, as well as discolored or degraded plastic fragments. By accurately detecting and separating these contaminants, plastic color sorters help maintain the purity of the recycled plastic material, ensuring that it meets the stringent quality standards required for various applications.

In addition to recycling, plastic color sorters find applications in the production of virgin plastic materials. In manufacturing environments, these systems are employed to ensure the consistency of plastic pellets or granules used as raw materials in the production process. By eliminating any deviations in color or composition, plastic color sorters contribute to achieving uniformity and quality in the final plastic products.

Moreover, plastic color sorters play a crucial role in compliance with regulatory standards and environmental initiatives aimed at reducing plastic waste and promoting sustainability. By facilitating the efficient sorting and recycling of plastics, these systems help minimize the environmental impact of plastic production and consumption, thereby supporting efforts to create a more circular economy.

In conclusion, plastic separator machine represent a critical technology in the sorting and classification of plastics, with applications spanning recycling, manufacturing, and environmental sustainability. By enabling the accurate identification and separation of plastic materials, these systems contribute to improving the quality, efficiency, and environmental sustainability of plastic production processes. As the demand for high-quality plastics continues to grow, the role of plastic color sorters in ensuring product purity and consistency is likely to become even more indispensable in the years to come.