About Us

Anhui Hightech Equipment Co.,Ltd

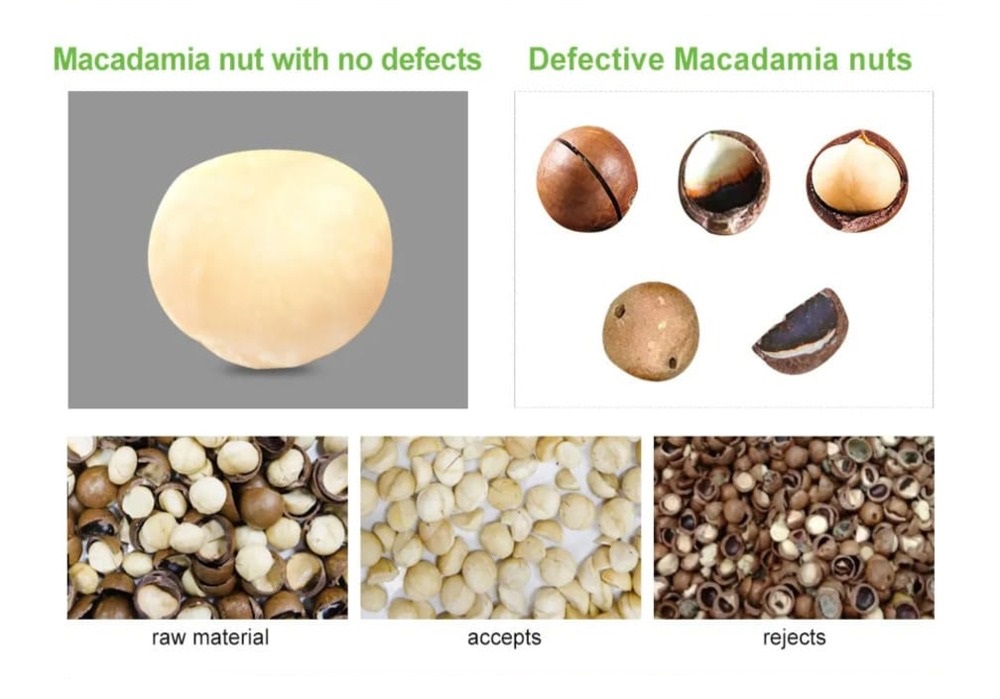

Anhui Hightech Equipment Co.,Ltd is a professional high-tech enterprise specializing in the R&D, production and sale of intelligent color sorters. Our intelligent color sorter has been widely used in many industries in the world. Such as agricultural products, food and mining industries etc.At present, our main products are plastic color sorter,ore sorting, rice color sorter, grain color sorter, bean color sorter, coffee bean color sorter, sesame color sorter, sunflower seeds color sorter, melon seeds color sorter, Dehydrated vegetable color sorter, raisins color sorter and other optical sorting machines , to meet the needs of different customers color sorting need. In addition, we an also be based on the actual needs of customers, providing a complete set of design, installation and technical training and other services. With a R&D team of solid technology and knowledge and entrepreneurial spirit, and cooperating with many domestic famous universities ,we are dedicated to the satisfactory of customers, constantly improving quality, and innovation of technology and expanding new applications of our optical sorting machines. We are aiming at enhancing the life quality of people, and creating more social and economic benefit, by application our technology to accurately sorting and purifying the materials with tiny defects. Relying on the excellent product performance, our products have spread all over China and are successfully exported to more than 40 countries and regions, like USA、Pakistan, Sri Lanka, Vietnam, Brazil, Russia, Nigeria, Ukraine, Bangladesh, Philippine,Finland and Bulgaria etc. We adhere to the “excellent quality, reasonable price, prompt delivery capacity, and exceptional service” goals for our company to become your ideal partner in mutually business transactions. CE & CSA Approved All of our equipment have been approved by CE and CSA, we served 100+ clients in 26 states worldwide. We provide intelligence oriented color sorting process which controls by big data technology. Our Vision Our Vision is to ensure more effective results in mining industry, agricultural and food industry for color sorting machinery. Our Mission Supplying color sorting machinery and technical supports with minimal cost. Being one of the most technological, mechanical and technical leaders in color sorter processing machinery What We Do HIGHTECH Color Sorter have been engaged in the design, manufacturing, installation and sales of large quantity of Grain, Tea, Sea Food, Ore color sorting machines for many countries. More information about color sorter What is color sorter ? Color sorter also named sortex machine ,optical sorter or color sorting machine ,colour sorter is a type of technology primarily used in the food processing,agricultural industries ,plastic industries to sort various items—such as rice,quartz,nuts,plastic, grains or seeds—based on their different colors & different shapes & different materials. What dose a color sorter do ? Color sorters ensures the quality and purity of materials by removing items that are discolored, diseased, or contaminated,contributing to both consumer safety and operational efficiency. What application fields of color sorter? Color sorters are mainly used in the field of plastics, grains, ores, food, rice, seeds etc. ***Agriculture products color sorter Rice color sorter -----All kinds of rice like parboiled rice ,black rice,red rice,white rice,long rice ,paddy,brown rice,sorguhm rice millet etc. Bean color sorter----All kinds of beans like mung beans,fava bean,masoor,red lentil,chickpea,soybean,black bean,split lentils ,white bean,hulled lentil,coffee bean etc. Grain sortex machine----All kinds of grain like maize,rye,oats,quinoa,barley,wheat,buckwheat etc. Nuts sorter----All kinds of seeds like pecan,peanuts,hazelnuts,pine nut,pistachio nut,walnut ,cashew nut,almond etc . Seed sorters----All kinds of seeds like lotus seeds,sunflower seeds,pumpkin seeds,rose hip,mustard seeds,rapseeds,pepper seeds,sesame seeds etc. Spice color sorter----All kinds of seeds like dried chili,ginger,cardamom,pepper,clove,cumin,medlar,ect. Food color sorter---Dried seafood,Dried shrimp etc. Dried vegetable and fruit color sorter----Dried garlic,dried apricot,dried fruit,herbs,dried flowers,raisin,date,dried chili;olive,blueberry,coffee cherry,strawberry etc.. ***Industrial color sorter Plastic sorting machines----PET,PVC,PC,PP,PE,HDPE,LDPE,ABS,plastic pellet,plastic flake,PET bottle scrap flake,plastic granule etc . Ore sorting----All kinds of quartz like limestone,marble,calcite,feldspar,amber,etc. Metal color sorter----All kinds of metal like aluminum, copper, zinc,wasted metal,bronze,broken wire, brass etc. Glass color sorter----All kin...

Read More

Our Vision & Mission :

-

Ensuring more effective results from color sorting machinery.

-

Mechanical and technical support provided at minimal cost.

-

Be one of the most technological, mechanical and technology leaders.

English

English русский

русский italiano

italiano español

español português

português Türkçe

Türkçe

IPv6 network supported

IPv6 network supported